Flat rooflight

Keeping a minimalist aluminium structure is key to our innovative design. Our Flat Light™ Rooflights are extremely versatile in their design construction, allowing triple glazed and quadruple glazed options, which remain flush with the frame.

Frameless Flat Rooflights

Our flat rooflight system boasts large thermal breaks for unrivalled, tested glass U-values of just 1.0.

All of our flat rooflights are bespoke made and can accommodate various options including size, opening or fixed, colour and glazing.

Our frameless

Flat Light™ Rooflights are a firm favourite with architects, specifiers and installers across the UK.

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

Slide title

Write your caption hereButton

FROM £800.00 + VAT

bespoke MADE

FOR EACH PROJECT

High Quality

Materials

Excellent thermal performance

Manafacturers

Warranty

Glazing Solutions

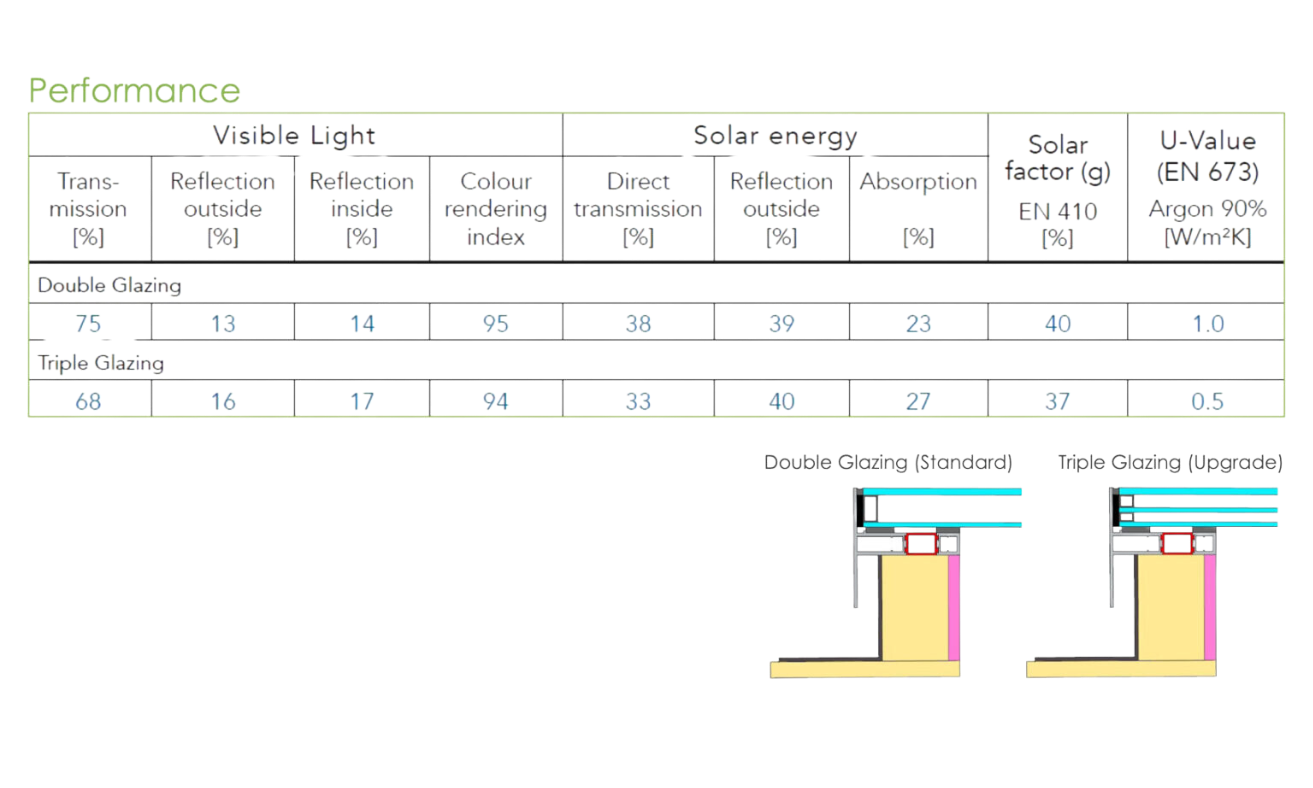

We offer a range of glazing solutions for flat roof applications. Our Flat Light™ skylight system boasts large thermal breaks to provide industry leading, truly tested, U-values. Providing a minimalist aluminium structure is essential to our flat skylight design, whilst also offering a very versatile frame construction that allows for double and triple glazing to be utilised yet remain flush with the frame. Let our flat skylight design provide a frameless glazing solution for your flat roof.

Our

Flat Light™ skylight system is produced using thermally broken aluminium which incorporates two 27mm polyamide inserts. These polyamide inserts reduce heat transfer through the aluminium and plays a big part in stopping both condensation and heat loss. To ensure that you are comparing like for like flat rooflight quotations, we would also advise that you check as there are some skylights and rooflight systems out there are just made of a single piece of aluminium and it will be highly unlikely that cheaper systems will have genuine thermal testing results so ultimately providing a far less thermally efficient product. In addition our flat rooflights use a triple seal gasket system to ensure industry leading weather performance.

Benefits

Another benefit offered by the Flat Light™ skylight is a 48mm frame overhang which provides an improved weather tight seal. Furthermore, our flat rooflight has no external fixings to significantly improve the weather proofing properties. To improve the installation process our frameless flat skylight glazing is supplied with metal fixings straps which are screwed into the internal timber upstand and then covered over with plasterboard, ensuring a perfect frameless look.

The Flat Light™ skylight should be fitted to a site built kerb upstand section which needs to provide a minimum pitch of 5 degrees and a maximum pitch of 40 degrees. The minimum pitch reduces the risk of water pooling on the flat rooflight glazing.

All of our flat rooflights are produced with bespoke sizes to suit your individual requirements. The majority of our flat rooflight products are supplied with one unit, to maximise the amount of natural daylight. The maximum size of our flat rooflights is dependent on the weight of the finished product and our ability to safely lift in production and manage the delivery. The bigger your flat skylight, the thicker the glass needs to be and by increasing the unit thickness you are also increasing the overall weight of the skylight.

Our expert team will be able to advise the most suitable glazing specification for your flat rooflight, taking into account safety, wind & snow loading and current regulations. With particularly large rooflights it will be necessary to divide the glass units using aluminium glazing bars. In this situation, your flat rooflight will be supplied in kit form ready for your contractor to assemble on site. We will supply all the necessary glazing tapes and silicones to achieve the perfect finish to your flat rooflight.

Dividing large flat rooflights with glazing bars also makes transportation and installation easier and removes the need for costly lifting equipment. You should always consider how you will unload and install your flat rooflight and if access and weight are an issue, we would recommend using the glazing bars and onsite assembly.

GLASS TO GLASS

For mid-range sized flat skylights the

Flat Light™ design allows for structural glass to glass jointing which provides a more frameless appearance. Still supplied in kit form for onsite assembly, the glass to glass option provides the maximum impact with the minimum amount of effort.

We use high specification glass in the manufacture of our flat rooflight products to ensure safety, longevity and outstanding thermal performance. Choosing a triple glazed flat skylight not only provides superb thermal performance but can also help with noise control which is ideal for locations with a lot of traffic noise. The glass thickness will depend on the size of the flat rooflight but our units will typically achieve centre pane u-value of 1.0 but this can be as low as 0.2. The glass used in our flat rooflights is coated with a durable easy clean coating to and allow rainfall to remove any organic dirt and grime. Whilst all our flat glazing products require some form of annual maintenance, an easy clean coating helps to reduce the amount cleaning that needs to be undertaken.

Our flat rooflights will typically be supplied with an inner pane of heat soaked toughened glass. Toughened glass is one of the most widely used glass products in the world. Up to five times stronger than standard annealed glass, it is also more thermally stable, withstanding sudden temperature changes which would cause laminated glass to crack. While toughened glass is much harder to break than annealed glass, when it does break it crumbles in its entirety into small, harmless pebbles. In most instances this means it is a far safer product to use, as there are no razor-sharp shards left behind.

THERMAL TEMPERING

Toughened glass is produced by a process called thermal tempering, where float glass is heated up to its transition temperature of around 650°C, when it begins to soften. It is then rapidly cooled, so the surface of the glass is cool, while internally the glass remains hot. This creates centre tension in the glass. On rare occasions, this tempering process can cause problems if the plate glass used has microscopic inclusions within it. Nickel sulphide particles formed in the production of the plate glass will cool down at a different rate to the rest of the glass. As they cool, they increase in volume, causing additional stresses within the toughened glass.

The result can be that the toughened glass shatters, seemingly spontaneously. While this is rare, when it does happen it can cause major inconvenience and be expensive to replace. The heat soaking process serves to ‘weed out’ any sheets of toughened glass that are liable to spontaneous breakage. Sheets of toughened glass stacked in the heat soaking machine are warmed to 290°C for several hours. Any nickel sulphide particles present will be forced to transform to their low-temperature state during the process, causing the toughened glass to shatter in a controlled environment rather than on-site weeks, months or even years after installation.

The potential risk of shattered toughened glass falling on people from overhead glazing means that heat soaking offers additional protection.

If your flat rooflight is situated at a height greater than 5mts above the internal floor level then you must have an internal pane of laminated glass. Laminated glass is constructed of two plies of glass which are bonded together with interlayers to form a permanent bond. The interlayers work to support and hold the glass to create a strong, uniformed layer even when broken.

Laminated glass comes in varying thicknesses and can be created using different glass combinations or coatings to provide different qualities. As laminated glass doesn’t shatter when broken, there is a reduced risk of someone being cut or injured by shards of glass.

Long Lasting Finish

Flat Light™

rooflights are finished in a tough and long lasting polyester powder coat. Our standard flat rooflights are produced in either RAL7016 anthracite grey or RAL9005 black. Unless otherwise requested the internal and external frame colour is the same however, we can offer dual colours if required. We can produce bespoke flat skylights in any RAL colour. This incurs a surcharge but please speak to our team for delivery times and pricing details.

Most flat roof glazing will be manufactured in a fixed, non-opening design. Not only are fixed flat skylights more cost effective but it also allows you to have bigger sizes. Where an opening rooflight is required we can provide a range of options, including manual, electric or an access rooflight version which opens to 90 degrees. If your flat skylight has an external manufacturing size which is 1200mm x 1200mm or smaller then it will be possible to operate it using our manual screw jack winder. Should your flat rooflight be larger than 1200mm x 1200mm then we can provide an electric actuation option. This is a small box which sits within the cill profile of the skylight and pushes open the casement with a chain. Opening distances can vary but the most common chain length is 400mm. The number of drives required depends on the casement size and weight. All Metal & Glass electrically actuated flat rooflights are supplied with a wireless remote control and rain sensor, which will automatically close you skylight when it is raining. Our electric actuators can be fitted to flat skylights which have a maximum manufacturing size of 2000mm x 2000mm or 1000mm x 3000mm.

Great product. We love working with it!

James Cambell, West Sussex

Amazing service. Can’t wait to find out what’s next!

John Applegate, West Midlands

Not sure what I did before discovering this Product. It’s super!

Sarah Thomas, London

Contact us any time

Have a question? We are here to help. Send us a message and we’ll be in touch.

Contact us

We will get back to you as soon as possible

Please try again later

All Rights Reserved | METAL & GLASS LTD

Company Number | 12113002